BP360A Industrial Cylinder UV Bottle Printer

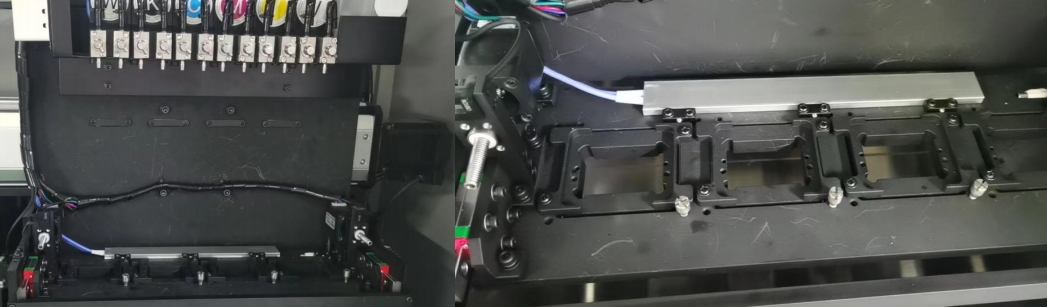

Professional bottle printing motherboard, printer work stable, high printing quality out put, less maintenance, longer running time.

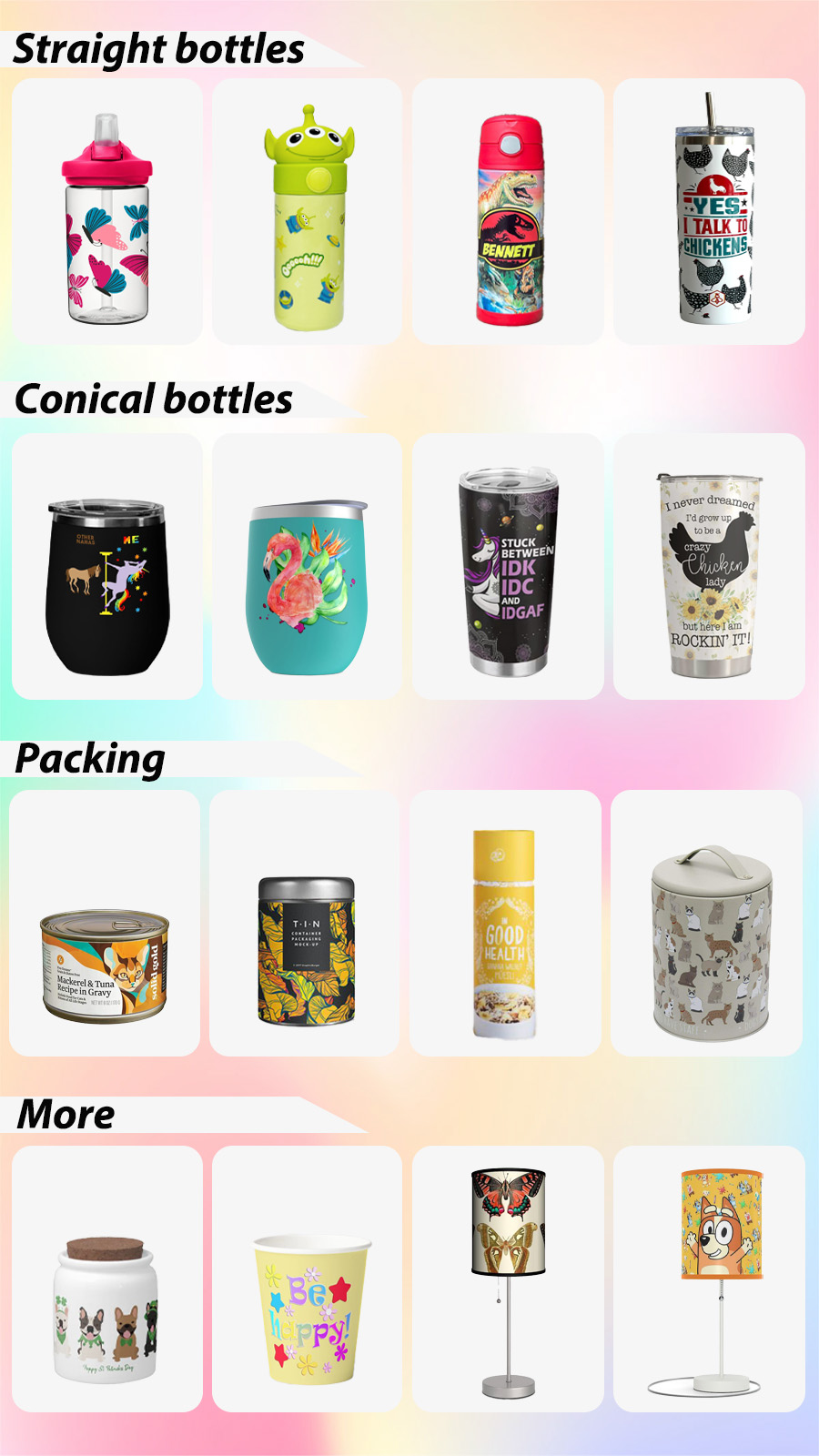

Support print white+cmyk++Varnish colors uv inks printing one pass on any shape bottles Support 3D embossed effect and varnish glossy effect.

Equipped with 3-4 pcs Japan Ricoh brand Gen5/Gen6 printhead,, it can print high quality and print stably.

Jucolor BP360A cylinder bottle printer use professional printing mainboard and system, all Line arrangement is neat and easy to maintain, control the printer more flexible.

Provides a variety of printing functions, support White+CMYK/CMYK,LC,LM,Grey,Red+Varnish inks print one psss, 3D embossed printing, varnish inks glossy effect printing, multi-image printing function, Ink detection, automatic detection.

Two advanced separate negative pressure systems. Simply and effectively. ensure the continuous ink flow, easy maintenance for multi- heads equipment. Reduce 90% printer failure and 50% maintenance time.

Effectively protect print head from being blocked, with more stable function capability, user friendly.

White ink bottle is equipped with a stirring system. motor drives stirring device to stir ink to keep ink does not settle. white ink tube is equipped with peristaltic pump to keep white ink circulates in ink tube and ensures ink not settle in ink tube. All ink bottles are equipped with alarm system, so that when ink is short, an alarm will be issued to note user to refill ink in time.

Cylinder bottle Printer is a high-precision device, which has extremely high precision requirements for print head base. It requires no height difference, no assembly gap, no deformation. Combined print head base cannot guarantee the flatness of the base, and it will appear as the printer's working time increases. Deformation, looseness, etc.

Integral aluminum alloy casting fundamentally solves the defects of mismatched base assembly, deformation, looseness, machining error, etc. It has extremely high flatness and never deforms to ensure high-quality output.

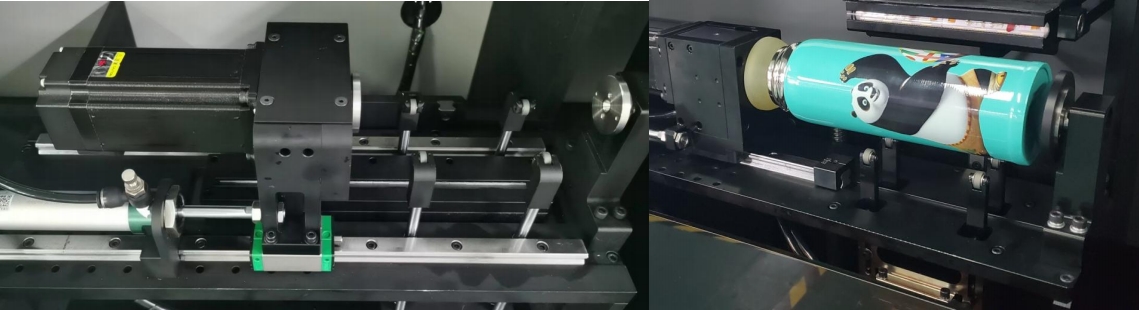

Jucolor team designed a professional bottle fixing fixture unit according to the shape of bottle and printing movement characteristics of bottle. It can fix and print bottles with 35-135mm diameter 30-300mm length, less than 30 degrees inclination. Special specifications can be customized. The system has the characteristics of quick fixture replacement, strong versatility, stable operation, low failure rate, etc.

Aluminum alloy printing platform & bottle fixing system.

The printing and fixing modules are made of aluminum alloy, which are processed by high-precision lathes to ensure the assembly accuracy, greatly reduce the vibration during the printing process, and improve the printing accuracy and the working life of the printer. The bottle fixing module can adjust the inclination of 0-30 to meet the printing of irregular bottles such as conical bottles.

New design bottle fix tray,quickly exchange different size bottle printing.

New design quick auto-release latches, reduce bottle fix and release time, improve printing speed.

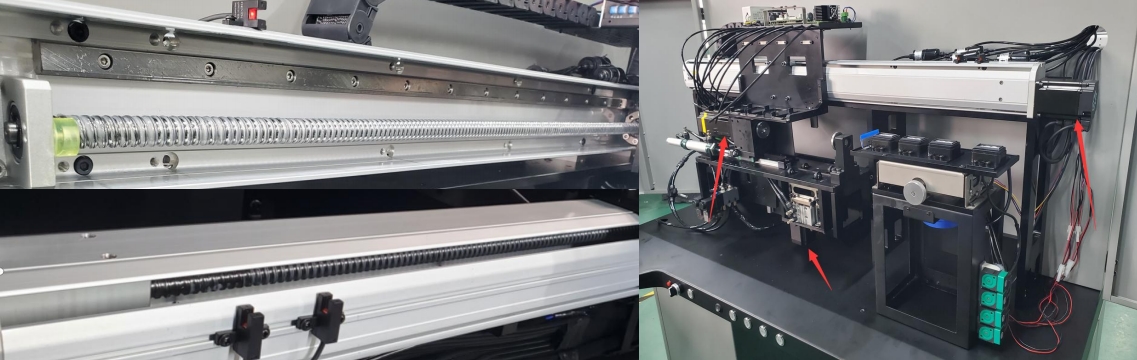

CJ-BP360A uv cylinder bottle printer is equipped with 3 sets of high-quality motors, which control movement of print head unit, Bottle

rotation, and high and low positions of bottle printing module Our motor can be trouble-free for 40,000 hours and has the characteristics of convenient replacement. print head unit moving motor uses a servo motor, which has the characteristics of high operation accuracy, long trouble-free operation time, and stable operation, which effectively improves the printing accuracy.

Print heads Motion Unit

We adopt Chinese Taiwan Hiwin brand silent guide rail, high-precision screw + servo motor to form print heads motion module Hiwin brand is famous for its high precision and low noise, we choose Hiwn brand guide rail, which greatly reduces the noise generated during printing. Screw has the characteristics of high-precision transmission, no deformation, no shrinkage, etc., and has excellent stability compared with belt transmission. Servo motors also have the characteristics of high speed, high stability and low failure rate. Through Print head motion module composed of precision guide rail + precision drive screw + high precision servo motor, it brings customers a better working environment, better printing quality, and less maintenance.

1.One year warranty

You can discuss operation and maintenance with our technician online support service by Skype, MSN etc. Remote control will be provided upon request.

2.Free exchange of new components

Our quality is guaranteed 100%, the spare parts can be replaced within one year free of charge includes the airfreight by express, except for the print head and some consumable parts.

3.Convenient online consultation

No matter what kind of technical questions that you may have, you would get a satisfactory answer from our professional technician easily.

4.Free onsite installation and training

If you are able to help us with getting the visa and also would like to bear the costs involved like flight tickets, food, etc, we can send our technician to your office, and to give you a free installation and training for as long as you know how to operate it.